Latest News

2024 UV+EB DEGRADABILITY CHALLENGE

This challenge highlights an important pillar of sustainability: designing products with their end-of-life (EOL) in mind.

RadTech Announces New Board Members

RadTech Announces New Board Members

January 8, 2024

RadTech Work Recognized by California Senator Anthony Portantino

Media ReleaseDecember 18, 2023 Rita Loof, director on environmental affairs, for RadTech, received the 25th Senate...

UV Fingernail Lamps Summary Information

UV Fingernail Lamps Summary Information

Resource information & links.

RadTech UV+EB Technology Expo & Conference | 2024 IUVA Americas Conference

RadTech UV+EB Technology Expo & Conference | 2024 IUVA Americas Conference

(Co-Located)

May 19-22, 2024 | Orlando, Florida

UV+EB Technology

The official publication of RadTech

RadLaunch

A Unique Idea Accelerator for UV+EB Start-ups, Students & Innovators

Buyer's Guide

products and services for UV+EB curing technologies companies

Events Calendar

Upcoming Meetings & Events

UV+EB Education

RadTech Young Professionals

Photopolymer Additive Manufacturing Alliance

Check out the latest UV+EB Applications

UV-LED Lithography Fabricates High-Resolution Miniaturized Optics

January 18, 2024

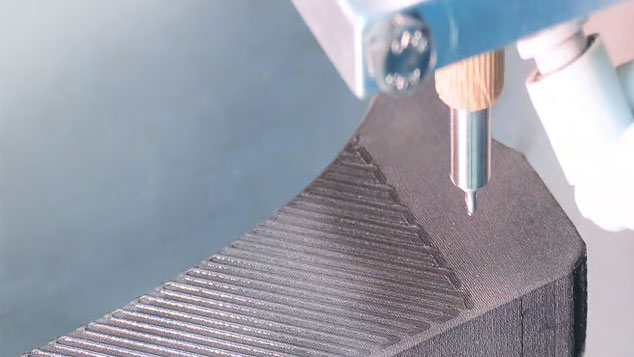

Chemists’ New Process Offers Safer 3D Printing Option, Requiring Less Energy and Cost

January 17, 2024

Mussel-inspired adhesive builds a bond between implants and bones

December 6, 2023

EUVAM project investigates energy-efficient UV process for composites curing

February 27, 2023

UV+EB in the News

- Global debut of Komori J-throne 29 at drupa 2024 - Packaging South Asia

- Electron beam lithography on nonplanar and irregular surfaces | Microsystems & Nanoengineering - Nature.com

- Global Additive Manufacturing Market Size To Worth USD 143.3 Billion By 2033 | CAGR Of 21.78% - GlobeNewswire

- Vat Photopolymerization 3D Printing Technology Market is estimated to reach US$30,037.738 million by 2029 - EIN News

- Fast Stereolithographic Printers - Trend Hunter

RadTech International North America | The Association for Ultraviolet and Electron Beam Technologies

6935 Wisconsin Ave, Suite 207, Chevy Chase, MD 20815 | (240) 497-1242 | uveb@radtech.org